This camera fits our large camera mount, which we sell separately here: Īlso note that camera sales are final - we do not accept returns, though we will replace units that are damaged or defective.

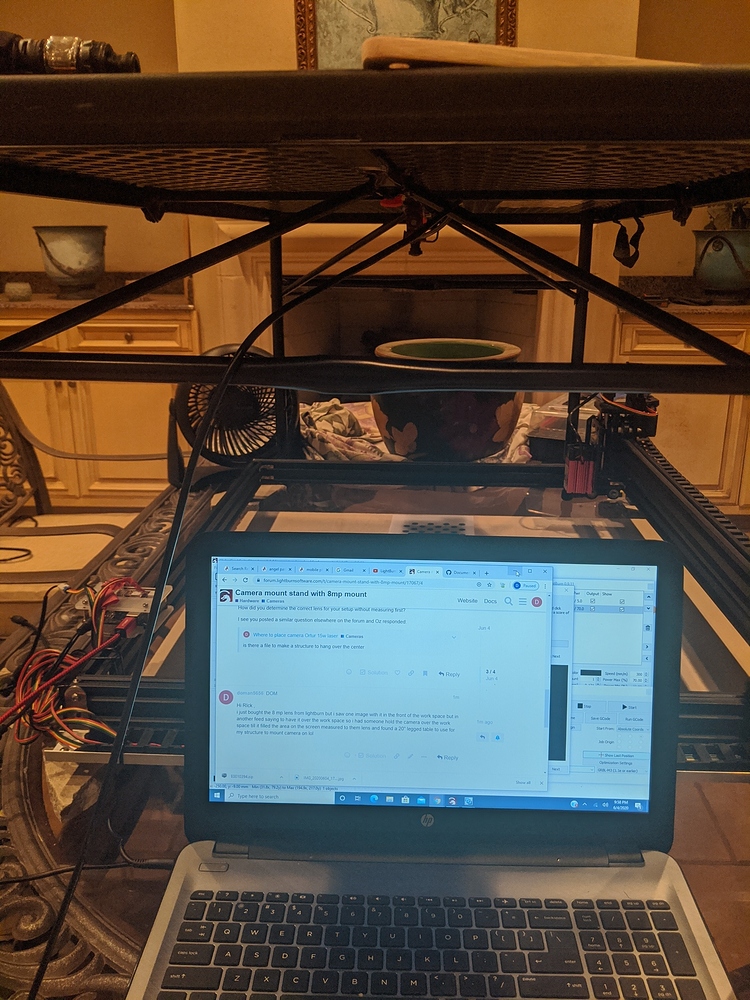

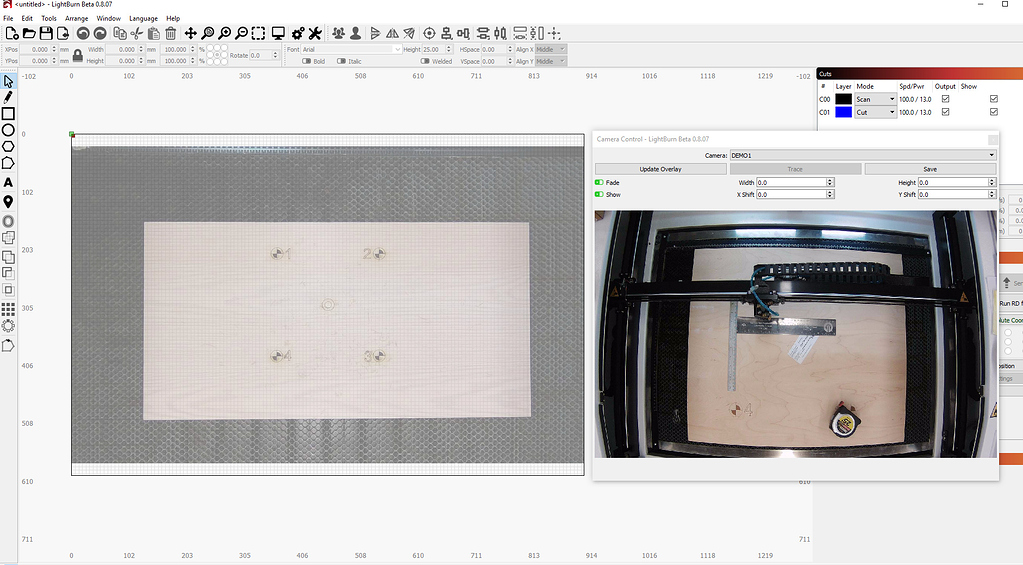

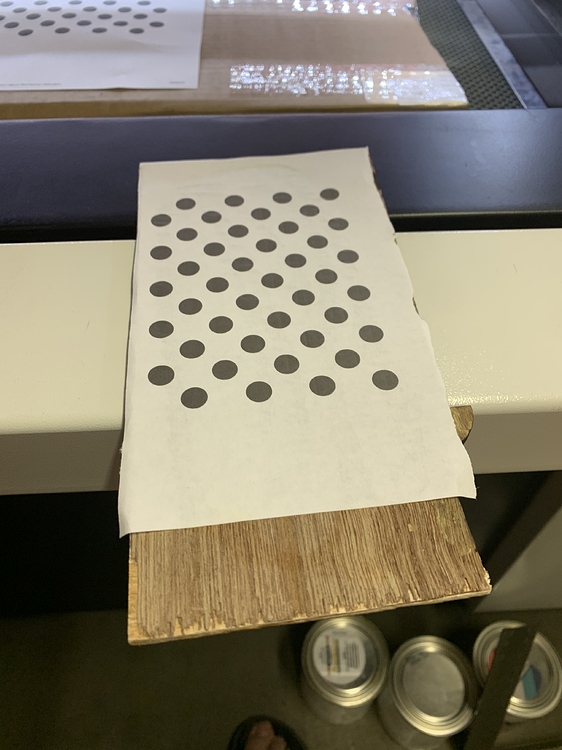

Note that these cameras are exactly as shown, with no enclosure. You will need to produce an enclosure or mount. The 110 and 95 degree lens variants are no longer available, and the 120 and 85 degree lenses are their replacements. 5 Lay a 12x12 board in the center of the laser bed. 3 In the Lens Calibration Wizard window, click Align Camera. No need to do a Frame function ore anything. Types of calibration.Calibration of a balance can be performed in two ways, either using internal or external calibration weights. A short demo on how easy it is to position an engrave/cut job on a work peace with the LightBurn Camera function. QC Representative a) Reviews analytical requirement. From the User Preset dropdown, select the 5megapixel 90 option.

Unsafe Materials - Never Cut These Materials! If you are not sure what a material is, don’t cut it! Using a laser on material that is not laser safe can create fires and toxic gases, which can be harmful or even DEADLY if inhaled. There are some presets for various camera types there but they did not work for my setup so I did a full calibration. So chose Tools/Calibrate Camera lens in Lightburn and follow the instructions. When in doubt, Google the name of the material + "MSDS" to find the Material Data Safety Sheet for that material. As most cameras have some distortion you have to calibrate the camera for your workspace. ** CO2 lasers only mark bare metals when anodized or treated *** WARNING: Because many plastics are dangerous to cut, it is important to know what kind you are planning to use.

0 kommentar(er)

0 kommentar(er)